The Context

Many of our industrial clients, in their quest to strengthen their market position, are undertaking large-scale CAPEX investments to expand, build new, or revamp their industrial capacities. Investing in these capacities is critical to achieving their long-term strategic goals, including capitalizing on market uncertainty to expand market share, to enter new markets, to decarbonize their production process (depending on the region) or to reshore supply chains. These investments often require commitments of 5 or more years.

These large-scale investments are not routine projects. Most of the time, they disrupt business as usual and require skill sets that are often unavailable or underdeveloped in-house. Navigating the construction ecosystem may also prove challenging to teams that rarely face such large and complex projects.

However, executing with excellence is not optional. Given the formidable amounts invested, any financial, schedule, or technical deviation may result in substantial ROI losses and hinder the overall growth strategy.

This article explores 3 essential guiding principles* that help lay the foundation for successful CAPEX execution.

(*) We believe these three guiding principles are essential to a project’s success, as indicated by the results of our 2025 CAPEX Survey that explores the top key success factors for management of large CAPEX efforts. Of course, many other factors exist and must be accounted for, that are not addressed directly in this article.

1. Anticipate the impacts of large CAPEX projects on your organization

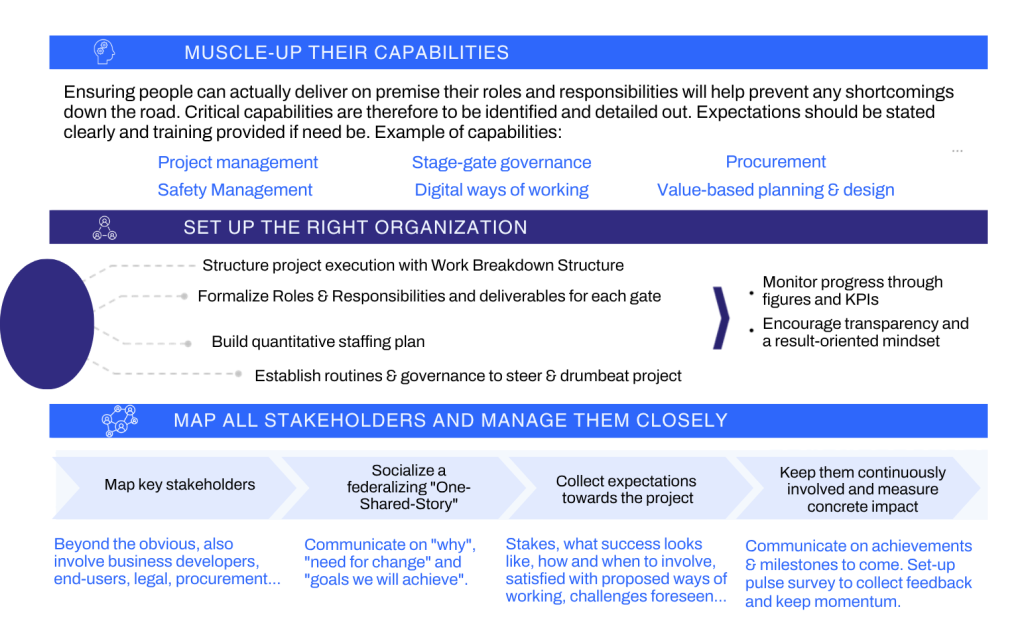

Delivering a CAPEX project may disrupt established ways of working. Teams are not likely to be on-time, on-cost, on-safety and on-quality if they do not adopt an appropriate operating model and organization. The challenge is amplified when projects involve 50 to 500+ stakeholders, often from diverse professions and backgrounds, who must collaborate intensively for a limited period under unfamiliar conditions.

To position a project for success and undergo the required changes, senior management may:

- Impact on project success: Winning behaviors enabled by a strong organization.

2. Start with the basics: align all stakeholders on real needs before selecting a solution

No two CAPEX projects are identical. Even when organizations standardize specifications across projects and streamline planning and execution, large capital investments have unique specificities requiring tailored solutions.

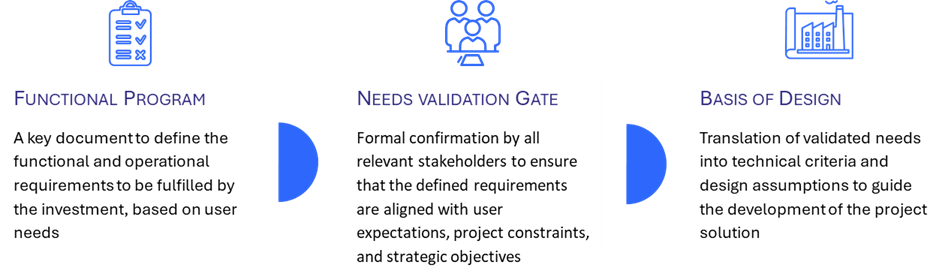

A common mistake is to jump into execution without verifying that real needs are solved by the solution. The consequence: the solution is often not optimized for cost, schedule, or quality. An inaccurate and misaligned definition of business need ranks among the top five causes of project failure, according to our 2025 CAPEX Survey.

Another common risk is that critical needs or key hypotheses – that should have been locked in early- are still challenged during the basic design or even detailed design phase! The results can lead to waste, lost momentum, and frustration amongst the teams. This not only threatens your ROI but also puts your teams under undue stress.

To mitigate those risks, a few basics:

- Map comprehensive requirements: document and validate commercial, technical, and operational requirements across all stakeholder groups.

- Build business scenarios: develop multiple scenarios to analyze business plan sensitivity to criteria such as market dynamics, supply chain, regulation, etc.

- Engage key stakeholders: involve end-users and key suppliers as early as possible and maintain this involvement all through the project, to challenge assumptions, identify innovative approaches, down-select solution pathways, and ultimately freeze the preferred scenario.

- Balance innovation and risks: strike the optimal balance between proven solutions and innovative alternatives that may offer competitive advantages.

- Impact on project success: Business and industrial objectives are supported by the right technical choices.

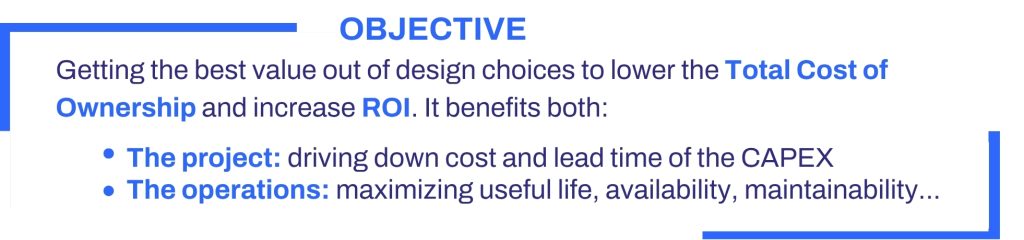

3. Design-to-Value

To make the Design-to-Value approach successful:

- Start with a robust baseline (Cost & Schedule). Building a strong baseline will take time and energy, but it should be considered as an investment. Low maturity estimates may lead to cost overruns and/or schedule delays! Benchmarking, expert assessment, parametric models, and supplier quotations are levers to ensure a comprehensive baseline.

- Optimize schedule alongside cost. For CAPEX programs, cost and schedule are strongly linked and should be addressed simultaneously (e.g., pay more to accelerate delivery, while preventing lost income from a delay of sales of client dissatisfaction). If needed, involving suppliers and contractors early helps identify risks and opportunities, while allowing the parties to grow as a team.

- From cost-down to value-improvement. Successfully employing Design-to-Value unlocks not only cost savings but also additional value from the CAPEX investment by fostering teams’ creativity (e.g., use of functional analysis to structure and search for both improvement (evolutionary) and disruptive (revolutionary) ideas. As an additional benefit, the cost savings achieved can also be reallocated to high-value technical options that would otherwise have been considered too expensive.

- Impact on project success: Maximized value gained from your capital expenditure.

Read more about Design-to-Value

Key Insights

Effective CAPEX projects involve more than just engineering and construction activities. They require a strategic approach that aligns technical execution with business objectives. By leveraging the three basic guiding principles above, organizations can maximize value, reduce Total Cost of Ownership, and support long-term industrial objectives.

Find out more about our CAPEX Performance expertise.