Since the 2015 Paris Agreement, manufacturers have increasingly focused on reducing their carbon footprint. While significant progress has been made on direct emissions (Scope 1) and energy consumption (Scope 2), many are now shifting their attention to the challenge of upstream Scope 3 emissions. These encompass indirect emissions not covered by Scopes 1 and 2, arising from the supply chain (suppliers, transportation & distribution activities, etc.). Reducing Scope 3 emissions is a crucial step that allows for the identification of overall environmental optimization and drives momentum across the entire value chain.

The manufacturing industry is prioritizing upstream Scope 3 emissions, which often account for the largest share of a product’s carbon footprint. However, managing these indirect emissions is inherently complex due to their wide-ranging and intricate nature. To address this, manufacturers need to engage a diverse group of stakeholders, sometimes encountering significant resistance. What strategies can industrial players employ to overcome these challenges?

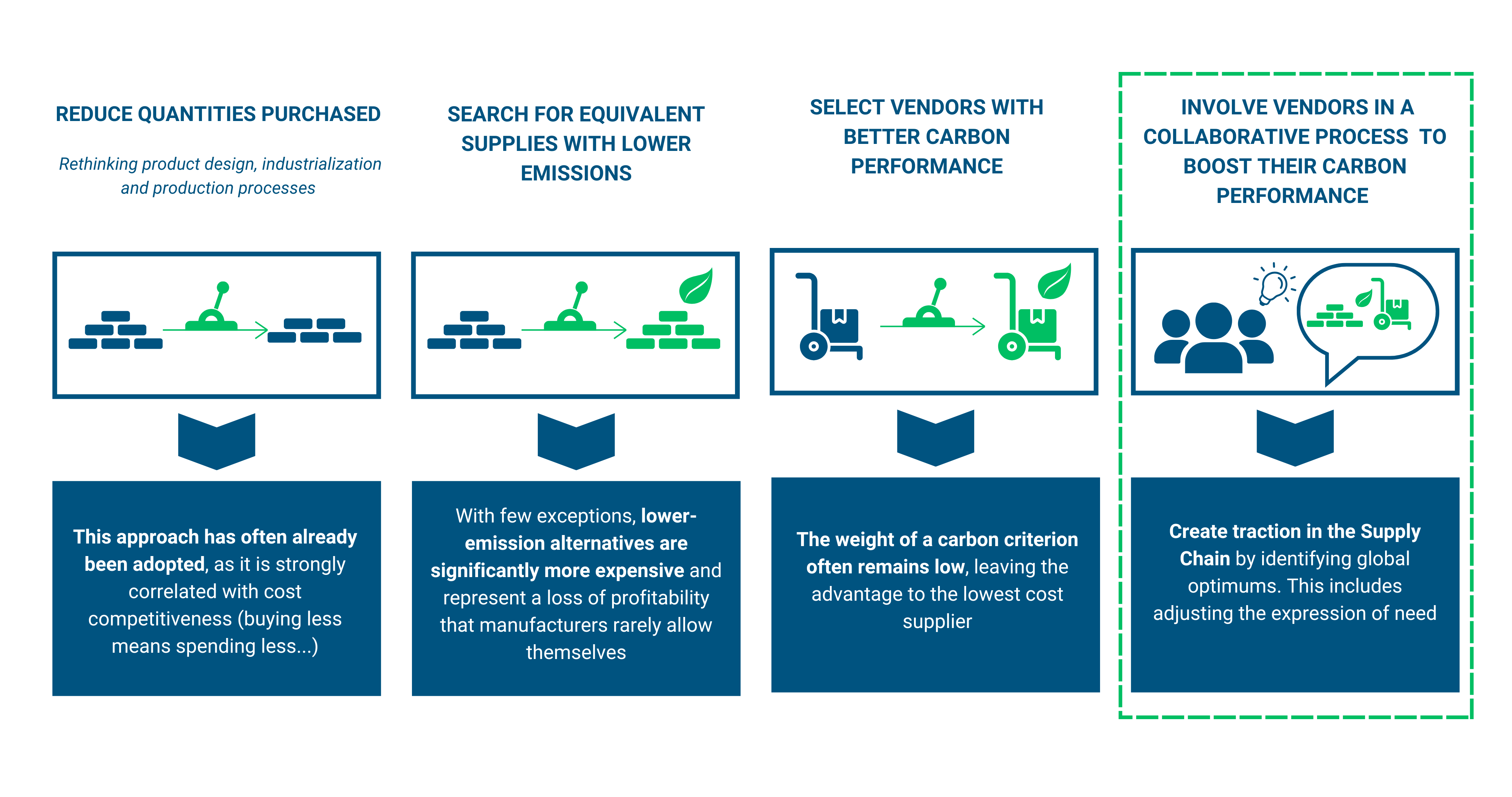

Scope 3 decarbonization: buy less, buy better and engage suppliers

There are four primary approaches to reducing upstream Scope 3 emissions. This article focuses on method #4: involving suppliers in a collaborative process. We believe this is the biggest hurdle for many companies.

A major obstacle: supplier’s reluctance to share data

A major obstacle is supplier reluctance to share data. Established customer-supplier relationships and non-replaceable products can facilitate engaging suppliers in improving the carbon performance of their supplies. However, some suppliers may hesitate to share sensitive data due to concerns about revealing strategic information regarding their processes and profits, potentially giving customers undue leverage.

Additionally, smaller suppliers might have limited resources and lack the maturity to provide complete data, while larger suppliers might not prioritize requests from smaller customers.

What are the solutions for overcoming obstacles and engaging suppliers?

Several tactics can help obtain data from suppliers, maximize response rates, and foster trust and transparency:

- Leverage Declarative Data

Many suppliers already participate in initiatives like the Carbon Disclosure Project (CDP) or Science-Based Targets initiative (SBTi). Accessing this “declarative data” allows for efficient creation of supplier emissions summaries, reducing the need for detailed raw data input.

- Transparency and Carbon Performance Criteria

Integrating “transparency and carbon performance” criteria into market share allocation processes can incentivize suppliers to prioritize these aspects. Regularly reminding suppliers that communicating relevant emissions data can avoid negative evaluations reinforces this.

- Identify the right contacts and bring them value

Activating and involving the appropriate level of management on both the supplier and client sides demonstrates the importance of the topic and ensures communication between relevant functions and levels.

Additionally, offering complimentary support to the supplier’s Corporate Social Responsibility (CSR) department in implementing carbon performance tools, training, and processes can be a valuable exchange.

- Unilateral Emissions Estimation

The “Reverse Footprint Assessment” method can be used to estimate supplier emissions based on their manufacturing procedures and material usage. Using slightly pessimistic assumptions can sometimes provoke a reaction and initiate collaboration.

- Developing Non-Financial Incentives

Providing non-financial incentives, such as joint communication campaigns, recognizes and motivates supplier decarbonization efforts. This can benefit suppliers by enhancing their reputation, expanding their network, or offering media exposure.

Implementing these methods and addressing Scope 3 decarbonization should not be seen as a burden. On the contrary, it’s a powerful tool for strengthening relationships within value chains. These initiatives not only directly and positively impact long-term industrial efficiency and competitiveness, but also transform the challenge of emissions reduction into opportunities for collaboration and innovation.

Authors: Maxime Bremond and Romain Grandjean