The Mission

Through reducing both cost and complexity the client aimed to make the sourcing of C-parts more efficient and transparent.

C-parts represent a major share of procurement effort in many industrial environments. Managing a high number of components and suppliers often leads to duplication, excess variety, and hidden cost.

The Solution

Our approach did not only access one lever, but two, to unlock the hidden potential of the C-parts portfolio.

1 | Standardization – Reducing variety across C-parts

- 3D analysis of unique parts and categorization by geometry and deviations

- Identified and evaluated 43-part clusters with the client’s operational teams to challenge part variance and variety of used materials

- Detailed assessment of clusters to validate and implement saving potential

2 | Supplier Benchmarking – Building a competitive supplier base

- Reviewed and revised MOQs based on defined calculation logic

- Performed a comprehensive RFI/RFQ campaign to identify new suppliers and to benchmark costs as input for renegotiation

- Shortlisted new suppliers for future collaboration through offer analysis and interviews, resulting in a qualification process

The Impact

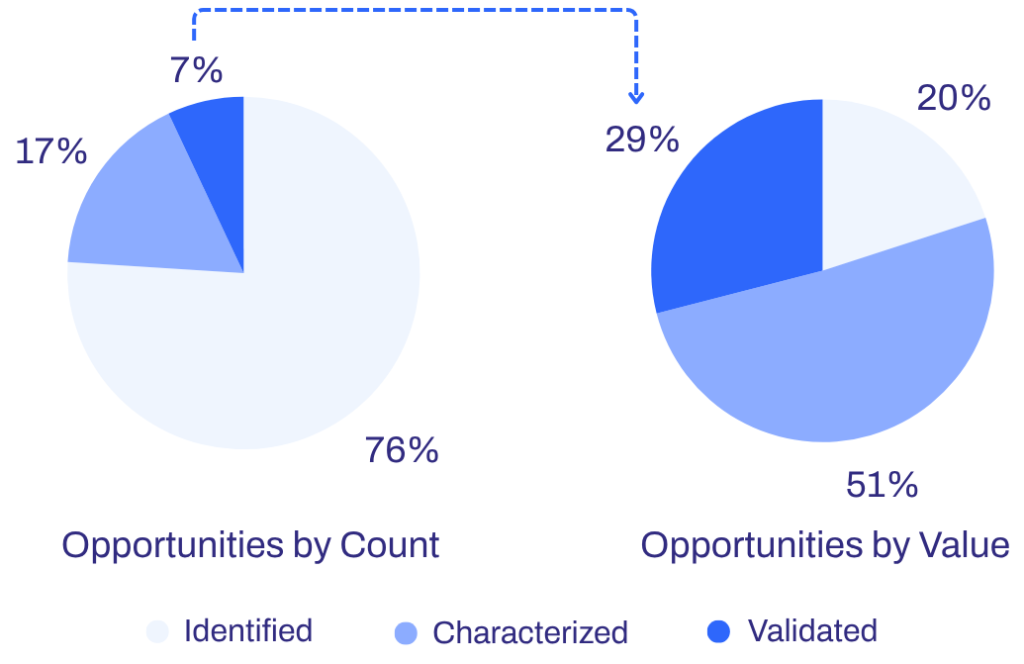

Through the combined levers of standardization and supplier benchmarking, we identified cost-saving opportunities of 13% across the entire C-parts portfolio.

Interestingly, validating just 7% of all identified opportunities already represented 29% of the total saving potential — showing how focusing on high-value levers can generate disproportionate impact.

The Secret

A key success factor was the strong engagement of the client’s purchasing team, which was motivated, open to new approaches and working closely with our consultants. Supported by an AI tool for standardization analysis and Avencore’s supplier database for benchmarking, the project stayed focused on the most impactful improvement levers.