Many industrial CAPEX programs fail to meet cost, schedule, or quality objectives. This article explores proven methods to turn around underperforming CAPEX projects: rebuilding governance, cost control, and execution discipline to secure industrial performance.

Why industrial CAPEX Programs drift, and how to detect early warning signs

Every industrial leader has faced it at least once: the CAPEX program starts with clear ambitions but soon drifts. Budgets expand, schedules slip, and alignment across engineering, procurement, and management erodes.

Typical symptoms appear quickly:

- Meetings multiply while decisions stall or occur at the wrong level

- Senior managers get drawn into operational firefighting

- Functions pursue separate priorities with no big picture

- Suppliers work on outdated drawings, etc.

For executives, this is not just a financial concern. It threatens ROI, credibility with the board, and ultimately, the ability to deliver on strategic commitments.

Why CAPEX discipline is a strategic advantage

In today’s capital-intensive industries, investment agility has become a strategic differentiator. When markets tighten, the ability to steer large CAPEX programs with precision determines not only short-term ROI but long-term competitiveness. In a constrained economic environment, investment volumes are limited and the few CAPEX programs that do move forward are truly decisive for the company’s future. There is simply no room for failure.

These programs often span years, involve thousands of interdependent activities, and rely on expertise (project management, engineering, procurement, cost control, scheduling, risk management, commissioning, HSE, contract management, etc.) that are scarce or dispersed. Missteps in governance, planning, or supplier management can quickly cascade into overruns and delays.

The good news: even when a program is off-track, recovery is possible. Success does not come from adding complexity, but from restoring clarity, structure, and momentum. The following levers have helped industrial companies regain control and deliver programs on time, on budget, and at the expected level of quality, while maintaining safety, people, and environmental performance at the core.

1 – Rebuild CAPEX governance and project structure to regain control

When a CAPEX program falters, governance issues are often at its core. Teams lose clarity on who decides, who escalates, and who delivers. Stakeholders pull in different directions, and meetings proliferate without decision. Without structure, even the best technical solutions fail to materialize.

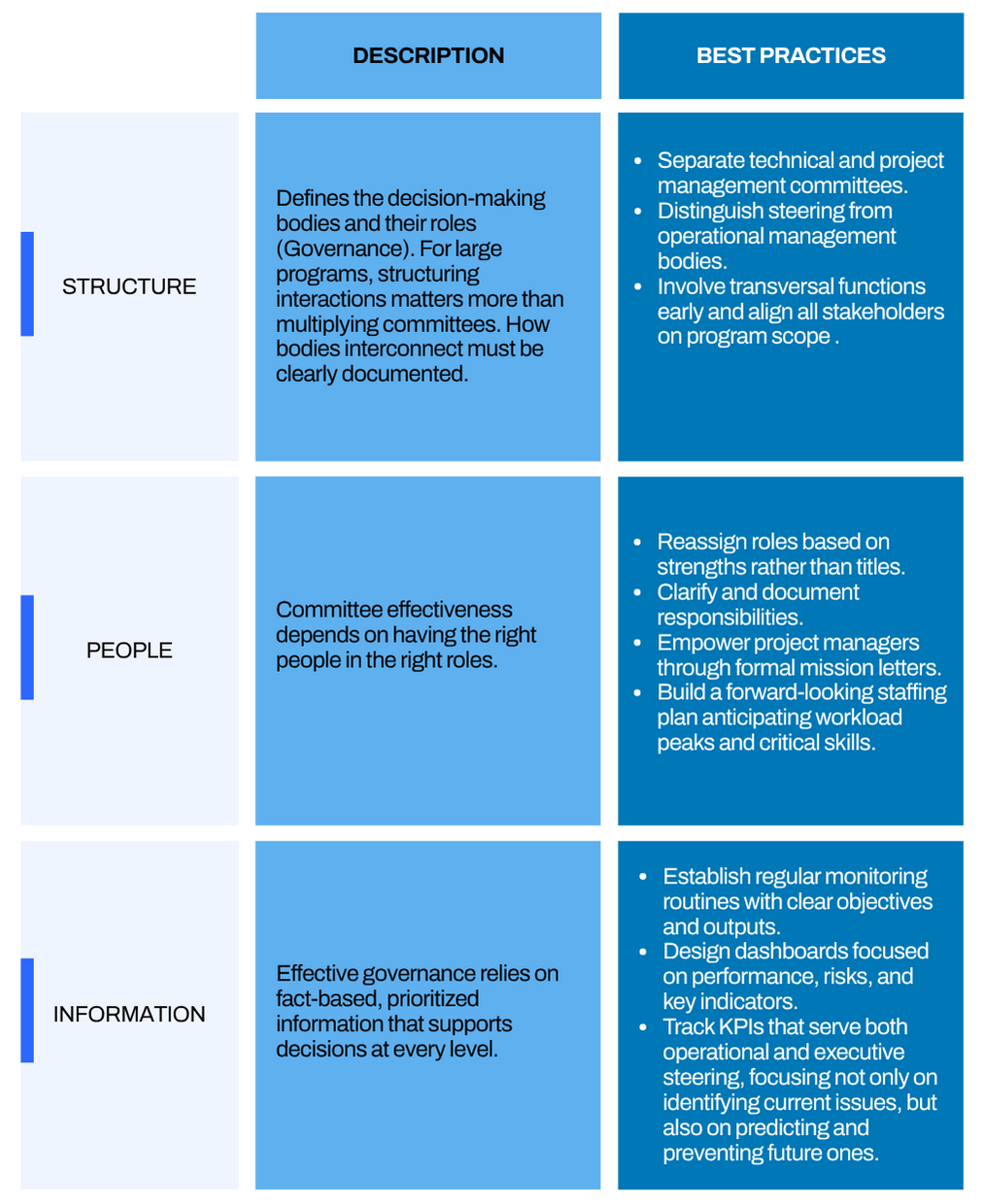

Project governance is the framework within which decisions are made, and accountabilities are exercised. Strong governance rests on three pillars: structure, people, and information.

Governance in CAPEX programs is not a one-off fix; it strengthens progressively as clarity, rhythm, and trust return. Initial gains come from restoring cadence and decision flow, while lasting improvement emerges as teams internalize new ways of working.

A properly staffed and empowered PMO can further anchor these improvements. It orchestrates routines, coaches stakeholders, and enforces discipline, accelerating recovery and sustaining momentum over time.

CASE STUDY – AGRIFOOD

A €150M CAPEX program involving 40 stakeholders regained control in just six weeks by re-establishing clear governance. Decision time was reduced by a factor of three.

“Once roles and rhythms were clarified, everyone stopped running in circles. We were finally managing the project instead of being managed by it. The clarity we regained transformed energy into execution!” — Program Director

2 – Reestablish and align CAPEX cost and schedule baselines

Another cornerstone of a successful turnaround is rebuilding credible cost and schedule baselines, aligned with the Work Breakdown Structure (WBS). Without this alignment, teams face multiple conflicting “truths,” leading to confusion and inconsistent steering.

Developing such baselines requires rigor. A planning baseline can include thousands of activities, and cost baselines often combine estimates of varying reliability. To make them robust:

1) INVOLVE THE RIGHT CONTRIBUTORS FROM DAY ONE (especially end users),

leveraging benchmarks, expert input, and supplier quotations to validate assumptions. A top-down estimate offers a valuable initial perspective, but developing a bottom-up estimate should remain the end goal to ensure completeness and accuracy.

2) ASSESS THE MATURITY OF EACH FIGURE,

distinguishing between rough estimates, RFI responses, and RFQs. This provides visibility on data reliability.

3) LEVERAGE DIGITAL TOOLS TO REBUILD TRUST.

Digital project control tools can further accelerate recovery by providing a single, real-time view of cost and schedule deviations, they help decision-makers anticipate, not just react.

By structuring CAPEX recovery efforts this way, organizations not only speed up the rebaselining process but also reinforce credibility: every stakeholder can see how figures were developed, how reliable they are, and what remains to be secured. The baseline becomes a shared and trusted foundation, not just a document.

Once baselines are secured, they serve as the true starting point for optimization:

- On the schedule side, they enable a critical path analysis that aligns management and project teams on a shared plan.

- On the cost side, they open the door to Design-to-Value initiatives to optimize total cost of ownership and ROI (see our article Mastering CAPEX Investments).

In a recovery phase, dedicated task forces are often the most effective structure. They ensure concrete progress week after week, rather than endless discussions.

TASK FORCE SUCCESS FACTORS

- Limit parallel task forces to avoid resource dilution.

- Give each task force a clear mandate and measurable objectives.

- Follow a structured roadmap, progressing step by step.

- Maintain high-cadence routines and daily or weekly rituals.

- Use centralized, transparent tools to share data and decisions.

- Report progress quantitatively, with clear visibility on gaps and next steps.

CLIENT INSIGHT – HEALTHCARE

“In just two weeks, we were able to clearly quantify how far off track we were: about +17% over budget. That clarity gave us a solid foundation to focus our efforts and start bringing the program back within target.” — Program Director

3 – Strenghen the Engineering X Procurement interface to improve CAPEX performance

A frequent root cause of CAPEX performance drift is the disconnect between engineering and procurement. Designs evolve faster than sourcing plans, suppliers are involved too late, and purchase orders (POs) stagnate without visibility, creating waste, delays, and cost inflation. The turnaround depends on rebuilding this interface in three steps:

1) STREAMLINE PROCESSES, CLARIFY ROLES, AND ENGAGE PROCUREMENT EARLY

Formalize procurement steps and make them visible to engineering teams. Engineers must understand lead times, sourcing constraints, and approval workflows to anticipate supply chain bottlenecks. At the same time, procurement teams should engage earlier, without waiting for fully frozen designs to start discussions with suppliers. Early supplier dialogue helps validate technical choices, lead times, and cost assumptions — reducing rework and accelerating final alignment once specifications are finalized.

2) CREATE A SHARED VIEW OF SOURCING PROGRESS

Centralize PO tracking through digital dashboards and standardized routines (weekly joint reviews between engineering, procurement, and program management). This ensures early detection of late or critical items and a unified list of priorities. Beyond execution, this shared vision should start early — aligning on long-lead items, sourcing priorities, and supplier readiness. Early visibility builds ownership across teams and prevents last-minute surprises downstream.

3) FACILITATE DECISION-MAKING THROUGH DATA VISUALIZATION

Consolidate key data to highlight PO status, pending actions, and risks in a way that drives executive arbitration. Visual tools reduce debate and focus energy on the next decisions that matter.

Reinforcing the Engineering X Procurement interface brings transparency, reduces late surprises, and secures both cost and schedule. What was once a source of friction becomes a driver of performance and a collaboration engine – enabling engineering and procurement to work together to enhance design efficiency, anticipate constraints, and accelerate execution.

Each successful turnaround doesn’t just restore control. It strengthens the organization’s ability to plan, decide, and execute future investments more effectively.

CASE STUDY – ELECTRIC BATTERY

In one turnaround project, implementing weekly joint reviews and shared PO tracking dashboards reduced average PO lead time by 40% in less than two months.

“Once engineering and procurement started speaking the same language, we stopped discovering issues too late. Decisions that used to take a month were

now made in a week.”” — Procurement Manager

Conclusion – Turning CAPEX overspend into sustainable value creation

Turning around a CAPEX program is never simply about adding more tools or more layers of reporting. It’s about rebuilding foundations: clarity of governance, credibility of baselines, and cohesion across engineering and procurement.

Programs that succeed in recovery share common traits:

- A governance model that restores confidence and decisiveness.

- A solid cost–schedule baseline serving as a single source of truth.

- Reinforced collaboration between engineering, procurement, and program leaders.

Beyond program control, these levers strengthen the organization itself, embedding project discipline, accountability, and transparency. CAPEX excellence is not the result of one-off fixes, but of routines and reflexes that turn complexity into execution power.

For industrial executives, the challenge is clear: regaining control of CAPEX programs is a lever not only for financial performance, but also for credibility, resilience, and long-term competitiveness.

KEY TAKEAWAYS FOR EXECUTIVES

- Back-to-basics: governance clarity accelerates decision flow

- A realistic, yet ambitious cost/schedule baseline restores confidence and focus

- Cross-functional alignment turns execution into performance

Find out more about our CAPEX Performance expertise.