Managing and reducing production costs are key priorities for success in competitive environments. Therefore, adopting effective cost optimization strategies is crucial for businesses.

In most cases there is actually no shortage of ideas for cost reduction. However, most opportunities require high investments and must take into account the interdependencies of multiple cost factors. In addition to asking about ways to reduce costs, industrial companies must consider the following crucial question: How can you ensure that cost reduction opportunities lead to the expected savings in the P&L and improve overall industry competitiveness?

The obvious approach to visible cost reduction would be to simply focus, sequentially, on the largest cost drivers (material costs) and eliminate some major constituents. However, the reality is more complex and an isolated improvement in one cost driver regularly leads to increased costs in others. At the same time, it may have an adverse impact on sourcing, production, quality defects, etc. Interdependencies between cost factors can even lead to an overall increase in costs instead of a reduction in production costs!

A sustainable cost optimization project should always start with a comprehensive process analysis and include all relevant areas of operations (production, logistics & supply chain, purchasing, quality, engineering, sales). Our experience has shown that only such a holistic approach provides a solid basis for decision making and highly outweigh the additional project effort in the mid and long term.

Case Study: When synergetic effects outweigh the potential savings from relocation

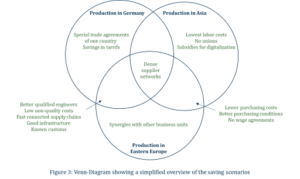

Our client in the household appliances industry was facing a market driven need for cost reduction on one of its high-runner products, exclusively produced in Germany so far. However, similar product lines were already being produced in eastern Europe and in Asia. The client asked us to define whether the production of this product should continue in Germany or whether it would be more cost-effective to merge with one of the similar product lines abroad.

Together with the client, we chose a more holistic approach, in five steps.

- Map the current situation in details

- Identify cost optimization opportunities & quick wins

- Assign the opportunities to scenarios

- Calculate savings for each scenarios

- Define an objective decision model and a clear roadmap

1. Record the current situation

To obtain a complete picture, the relevant steps of the value-added process were examined in detail. To keep the project efficient, we decided to focus on the following three cost areas, which together account for more than 95% of the product costs:

- Material costs were the largest cost driver. We examined the current supplier structure and the delivered parts and their variants to get all relevant information on the current status for a subsequent definition of cost optimization opportunities.

- Production costs were analyzed through a thorough mapping of every single production step in terms of a value stream analysis including investigation of throughput time, resources/capacities and information flow to get an overview of the total production cost per unit.

- Logistics costs were assessed based on a bottom-up process analysis incl. storage time/condition, space requirements and the supply process (mainly in terms of how often a component is touched during the supply process before finally being “consumed”).

2. Define and categorize cost optimization opportunities & quick wins

As in many similar cases, the analysis phase identified many opportunities for improvement in individual process steps, material purchasing and logistics. These optimization potentials were divided into quick wins and long lead time potentials, mostly related to higher investments. In the specific project, we initiated the implementation of several quick wins, such as

- Digitalization of necessary documentation processes

- Preassembly of cable harnesses

- New arrangement of assembly tables

- Faster devices for end-of-line testing

- Use of tool belts for mobile workers

Leveraging quick win is crucial for the overall acceptance of the project and for the motivation and involvement of the relevant team members. So, it’s not just a quick win, it’s an essential catalyst for team’s engagement.

Further potentials regularly arise from

- Value stream optimizations

- Standardization to reduce unnecessary variance and bundle volumes

- Eradication of non-quality by e.g. process or design changes

- Make vs. Buy analyses and supplier workshops for e.g. long lead-time or expensive parts

- Indirect process optimization e.g. in order intake and planning

- Etc.

3. Assign cost optimization opportunities to potential scenarios

Opportunities that require large investments are often interdependent. To get a clear overview of the different ways to implement opportunities, they should be assigned to comprehensive scenarios. For reasons of efficiency, it is recommended to prioritize the opportunities based on feasibility and savings potential. However, the holistic approach is key: the trade-off between the individual potentials and the impact on other processes must be taken into account. In the case of our project, the breakdown of potentials by production site and the impact on other sites was a relevant criterion. Be aware that when creating scenarios, previously unconsidered or unquantified process steps may become apparent and must be calculated in the following step.

4. Calculate potential savings for each scenario

The opportunities, which up to now have only been roughly sorted by feasibility and savings potential within the scenarios need to be quantified in the next step. This process often requires experience values and KPI from similar projects like e.g. for logistics costs in BCCs. Additionally, it’s crucial to consider qualitative factors, like differences in the legal framework, although challenging to quantify, during the evaluation process.

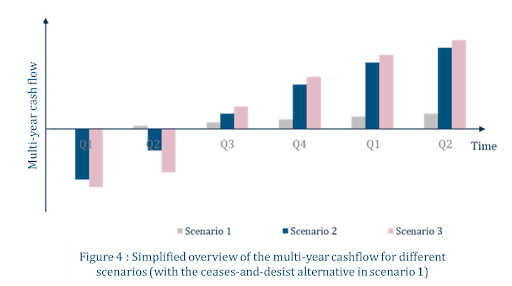

5. Prepare an objective decision model

The goal of this step is to clearly present the calculations and offer a comprehensive overview of the opportunities for savings, risks, and necessary actions to management.

In the specific case described here, it was first determined through a non-holistic approach that relocating production to Asia could potentially be profitable only for a variant of the high-runner product line under study. For this variant, the reduction in labor costs appears to offset the risks associated with increased supply chain complexity.

However, the holistic approach later revealed that the potential gains from relocating the variant are completely outweighed by the cancellation of actual synergistic effects due to the presence in the same location of the whole product line. The potential savings from relocating part of the production do not balance out the costs associated with increased efforts in engineering, sourcing, and knowledge exchange.

Looking only at optimization by product, relocating production to China might have seemed a good idea. However, it would have disregarded the global optimizations resulting from centralized production and the synergies with other portfolio products.

Authors: Manon Weichert, Norman Neupert and Christian Barysch