Addressing workplace ergonomics has long been a significant challenge in the industrial sectors, impacting operational performance and attractiveness. With longer professional careers becoming the norm, this issue is gaining urgency. Today, more advanced approaches—integrating root cause analysis with new technologies—are transforming the landscape for industrial players.

Together with industrial firms, Avencore is turning this shift into a real opportunity to improve not only operators’ daily experience, but also operations and business performance. Convinced that traditional methods and tools for addressing ergonomics fail to tackle the real issues (or only do so superficially), we have developed a specific approach. It combines insights from industrial experts, technology best practices, specialists in organizations and change management, and ergonomists.

Avencore’s Methodology for Workplace Ergonomics Solutions in Industry

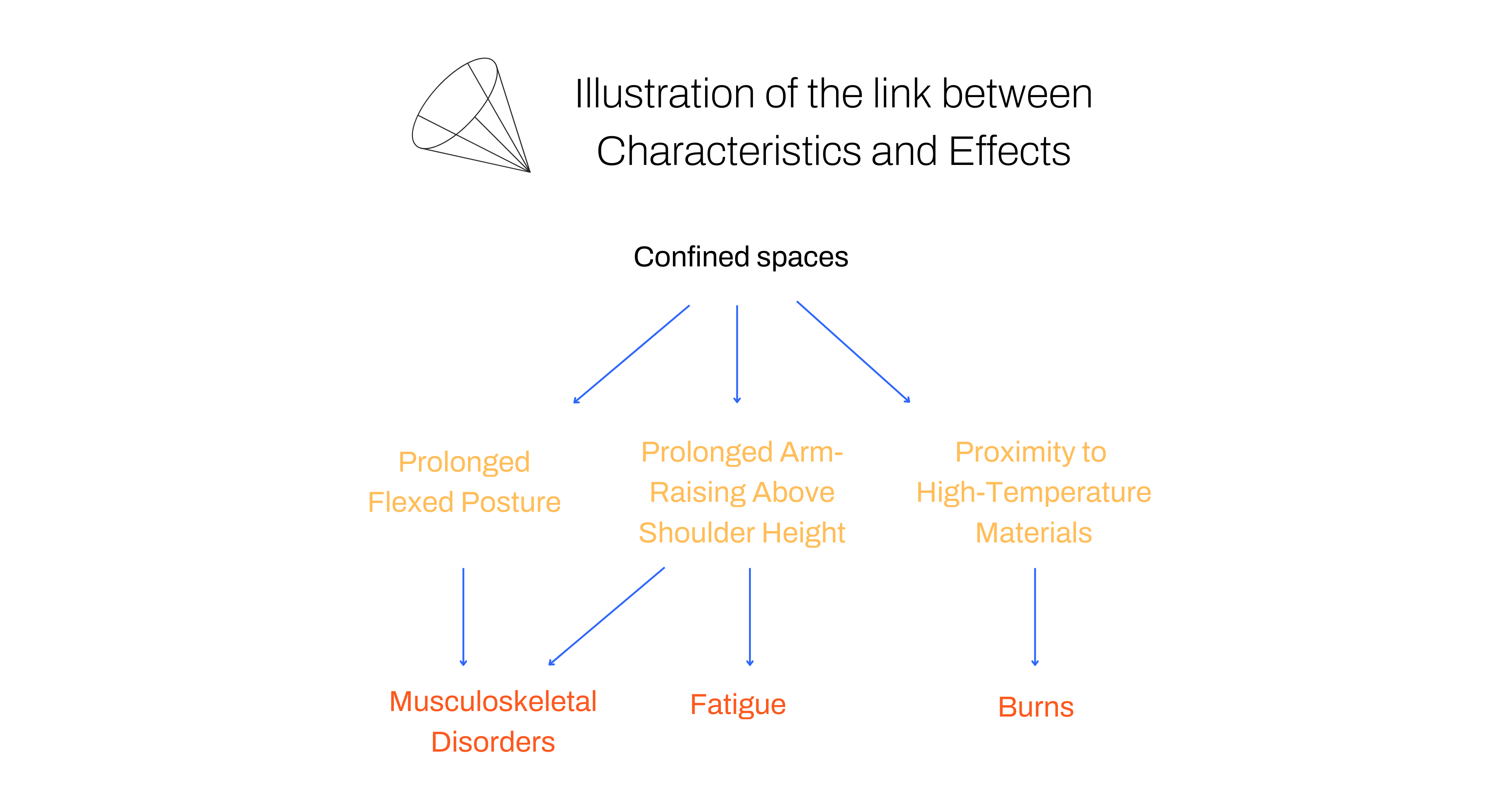

There is often confusion between symptoms and root causes. Too many industrial companies believe they are addressing a fundamental cause of ergonomics when they are merely alleviating a symptom. Treatment is often superficial, very localized, costly, and unsustainable. To address root causes effectively and achieve measurable impacts on operators’ symptoms, a systematic approach is essential. This involves modeling activity across three dimensions: characteristics, modalities, and effects

The challenging characteristics of tasks (confined spaces, vibrations, heavy loads, noise constraints, etc.) are intrinsic to the industrial environment, making them difficult and costly to eliminate. However, work modalities (e.g., sustained arm-raising above shoulder height), which are linked to these characteristics, can be effectively addressed. Tracing back to root causes enables us to solve the real problem rather than just the symptom. Once these root causes are identified and prioritized, technological, procedural, and organizational levers can be activated to evolve work modalities.

Leveraging Advanced Technology to Solve Ergonomic Challenges in Industry

This method is especially effective when proposed solutions leverage cutting-edge technology that meets the highest industrial standards, already implemented by industry leaders in work stress and safety management. By integrating automation, robotics, cobotics, artificial intelligence (combined with digital twins), and connected sensors, industrial processes can be optimized. More broadly, the right level of integration can relieve workers from the most challenging tasks, enhancing their safety, efficiency, and overall well-being.

Avencore’s Step-by-Step Approach to Scaling Ergonomic Solutions

Testing solutions on a limited scope (specific job, particular work situation, etc.) makes it possible to assess their effectiveness and identify initial quick wins. This also helps identify potential obstacles and anticipate the bottlenecks that could hinder the generalization of solutions when scaling up.

Successful scale-up relies on two key factors. First, the identified tests and early wins within a limited scope can drive effective change management. Second, the involvement of all levels—from leadership to managers, workers, and external experts—is crucial, as is raising awareness among teams. This includes training workers on new practices and technologies and implementing monitoring and evaluation mechanisms to track progress.

With targeted change management supporting the scaling process, we can then establish a catalog of quantified solutions and build precise implementation plans. Our role also includes projecting short-, medium-, and long-term benefits to justify and secure necessary investments. This approach maximizes positive impacts on worker health and ensures sustainable performance for industrial operations.

Building a Sustainable Future: The Role of Ergonomics in Industrial Performance and Worker Well-Being

In conclusion, addressing ergonomics in depth in industry remains a significant challenge. But it also presents an invaluable opportunity to improve working conditions, strengthen operational performance, and enhance the appeal of our industrial fields. This transformation requires the involvement of all stakeholders, from HR leaders to company executives, including managers and operators. Together, we can build a future where industry is synonymous with sustainable performance and worker well-being.