In the competitive landscape of modern industry, companies are facing a dual challenge: meeting customer expectations for innovative products while optimizing production efficiency and cost-effectiveness.

This challenge is even more demanding when external roadblocks come into play: rises in commodity prices, disturbance in supply chains, increasingly aggressive competition, new regulations, etc.

Since these challenges cannot impact delivery to end customers (in terms of delay, cost, or quality), companies often face a very specific problem: how to maximize customer value while managing costs throughout the product development lifecycle—this is Design-to-Value.

How to define Design-to-Value?

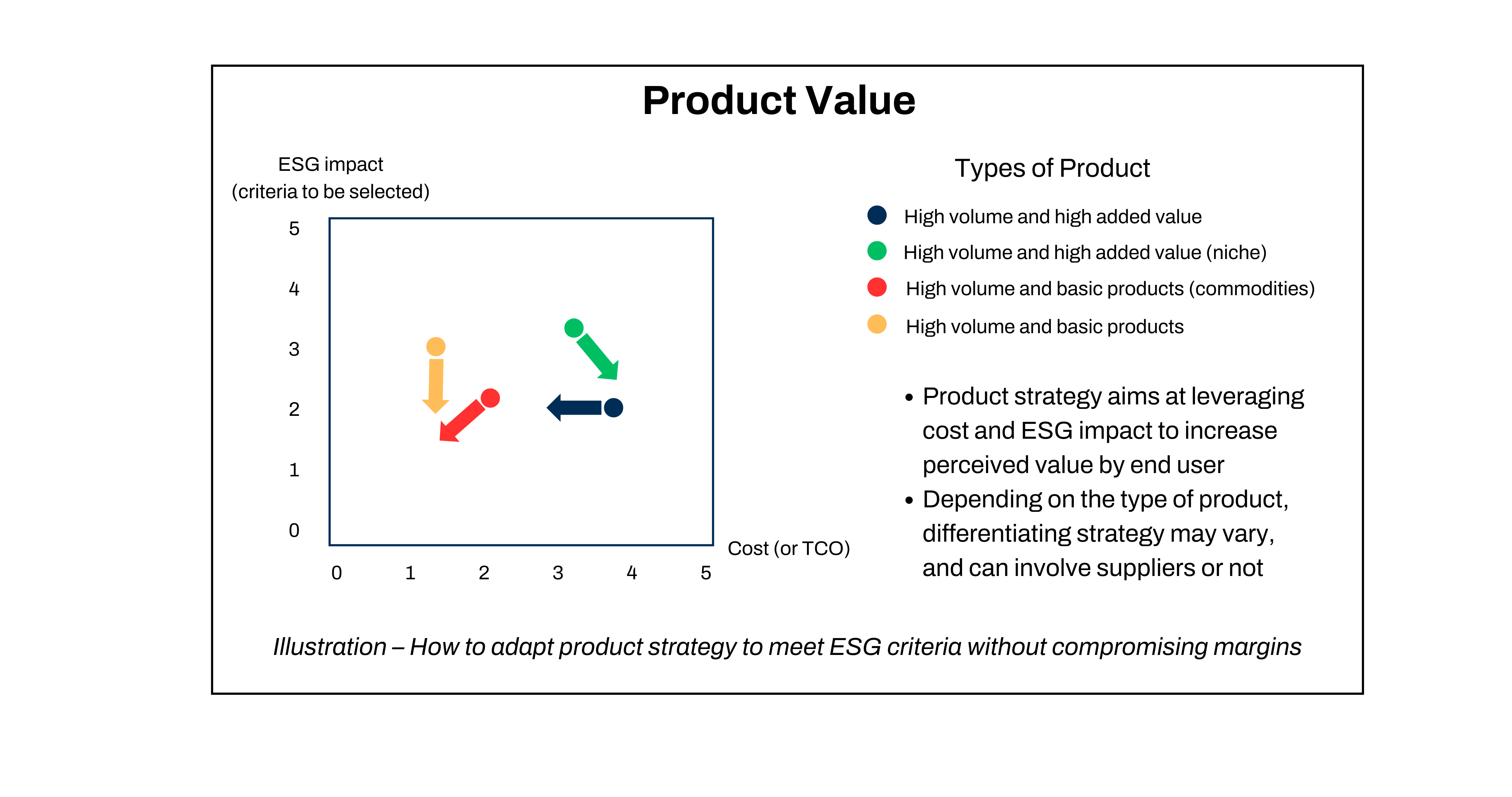

Design-to-Value (DtV) is a strategic approach seeking to increase the value / costs ratio through design and processes choices.

While (re)design-to-cost focuses on design changes to reduce costs, Design-to-value aims at maximizing the product’s overall value and customer’s satisfaction by balancing performance and cost, offering a more holistic approach to product development. Design-to-Value (and its more specific application that is Design-to-Cost) underscore the importance of an integrated product optimization approach that judiciously balances both cost and value, ensuring that companies can deliver competitively priced products without sacrificing quality or customer appeal.

Value must be clearly defined to ensure product performance alignment with market expectations and can vary from one customer to another. Value can encompass several dimensions, such as:

- Technical features (e.g. autonomy, max speed)

- Reliability and durability (e.g. MTBF)

- Lead time (e.g. 24h deliveries)

- Sustainability and eco-friendly practices (e.g. CO2 emissions in the product life cycle)

- Innovation (AI-driven predictions, etc.)

- Brand perception (high-end vs entry-level product)

- Etc.

In the objective of developing the most eco-responsible product on the market,

Avencore has helped a consumer goods industry to lower the carbon footprint of a new product range by 26%

Cost drivers have to be systematically identified and evaluated at every stage of the product development process: purchase of raw materials, engineering efforts, manufacturing steps, supply chain processes, etc.

Thanks to Design-to-Value, industrials manage to optimize their value proposition throughout the product development lifecycle, and deliver competitive, cost-efficient products that maximize customer satisfaction.

N.B: Design-to-Cost is only one dimension of the much Design-to-Value approach that focuses on reducing costs while maintaining the same value for the end customer.

Avencore has led more than 500 cost reduction projects, with an average of 20% cost reduction going up to 50%.

Why leaders need Design-to-Value to optimize cost and value at the same time?

Design-to-Value is increasingly used in all industries, from the simplest high-volume consumer good to a military vehicle of armed forces. With hundreds of Design-to-Value projects successfully completed, we at Avencore have identified 7 signs that Design-to-Value initiatives have to be urgently launched:

- An entry of new competitors or intensified competition within the industry, threatening your market share and pressuring your prices.

- A significant increase in raw material costs, labor expenses, or operational overheads, impacting profit margins and requiring a reevaluation of the production process.

- Customer reviews (or market research) indicating a shift in preferences towards specific features, functionalities, or sustainability considerations that your products may not correctly address (though it may not initially be clearly identified as such by the customer).

- An increase in customer complaints or a rise in customer churn rates indicating a disconnect between current offer and customer expectations.

- Shifting Market Dynamics with the emergence of new technologies or evolving regulatory requirements that signal a need for product adjustments.

- Lack of Innovation versus competitors (e.g. when demand for historically high-performing products is shrinking and captured by new products on the market), and a misevaluation of costs required for innovation.

- You’re about to launch a new product or sell to a new client, and you want to make sure your product – either in its core functionalities or the associated options- is perfectly aligned with client’s expectations.

Our method to drive your product design decisions.

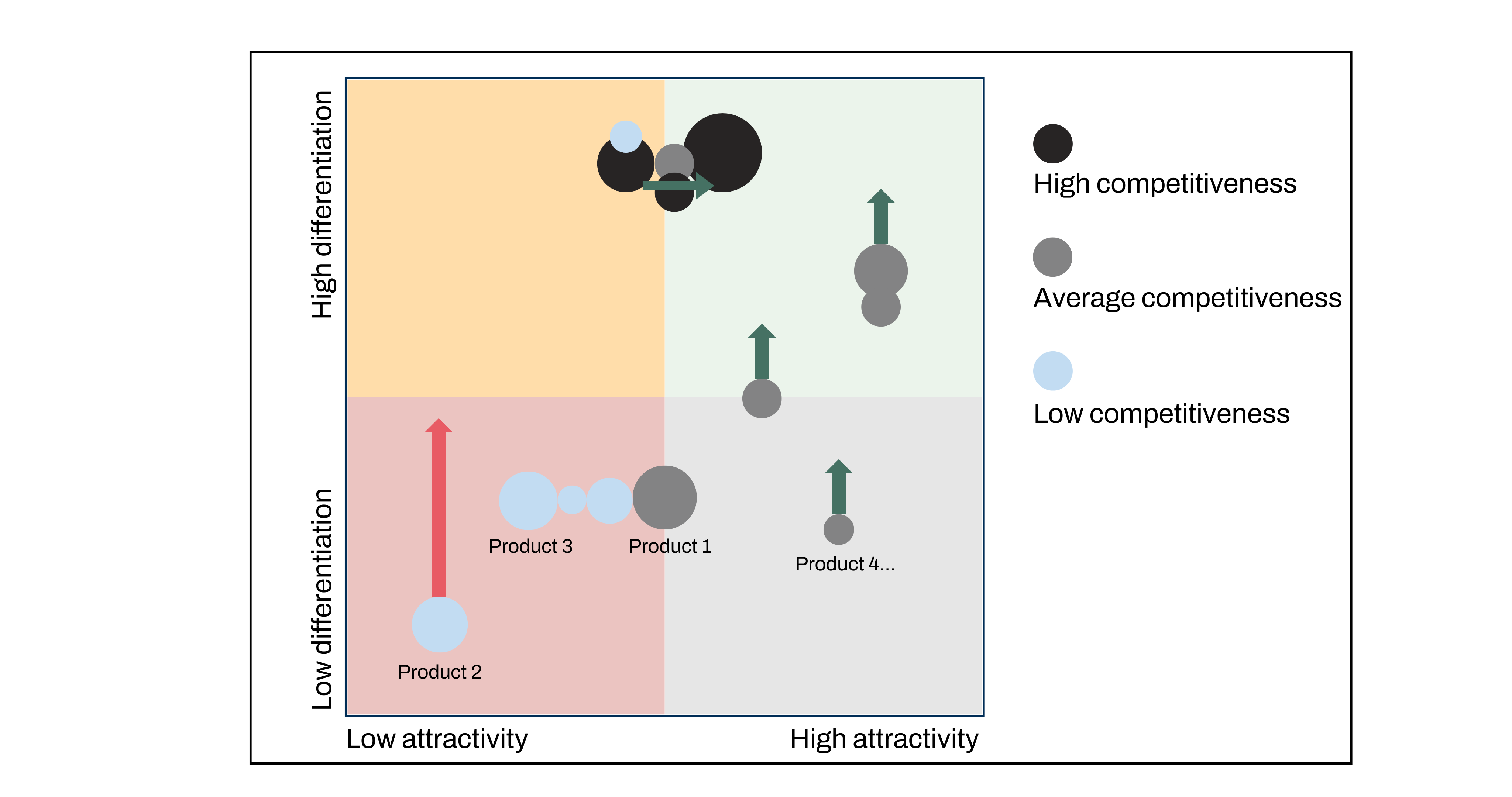

The first deliverable of the Design-To-Value methodology is a complete Value Analysis: the goal is to connect the customer requirements with the costs of your product components. Avencore has developed a 6-steps procedure for a successful Value Analysis:

1. Formalize customers’ needs

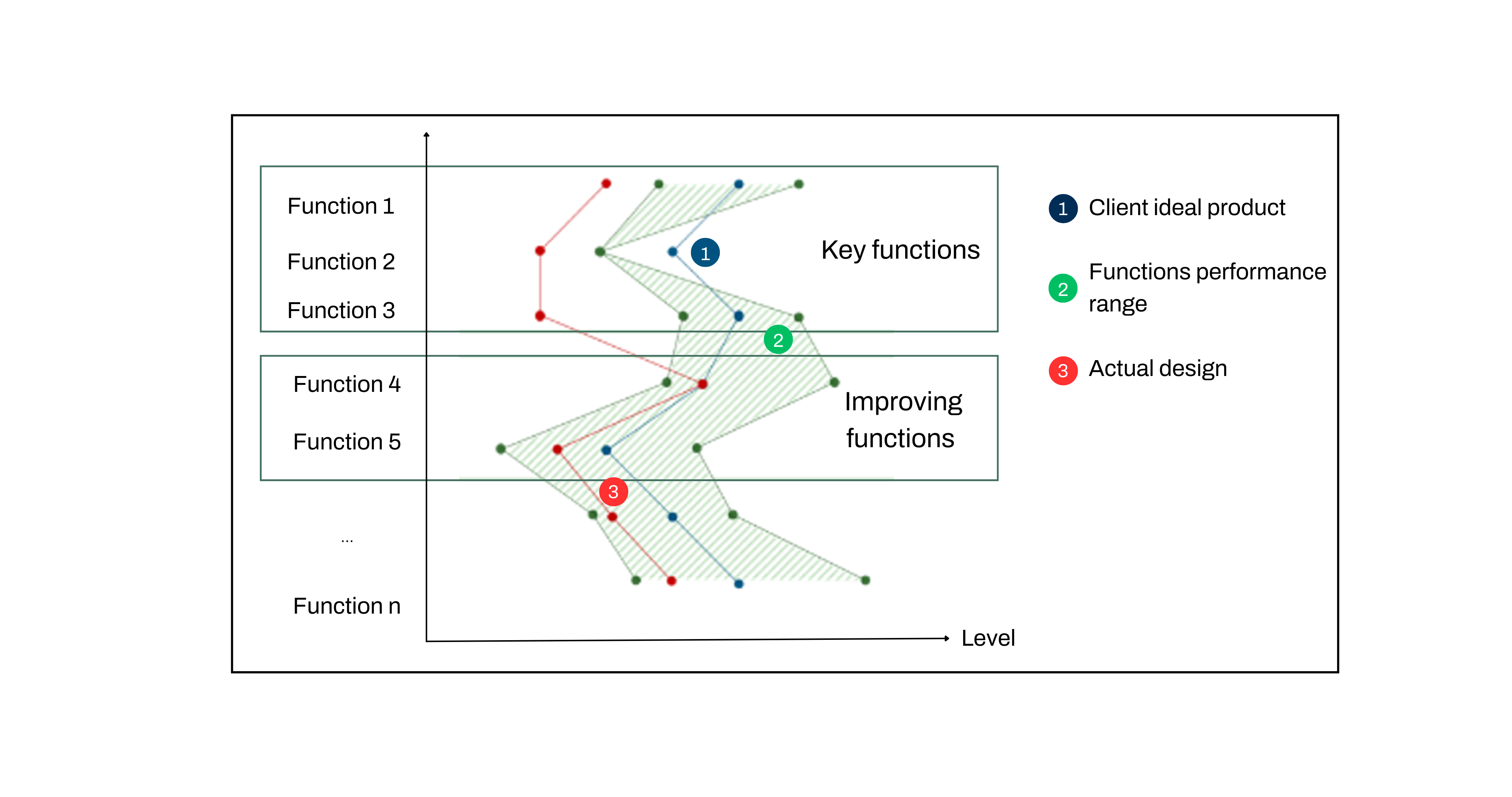

2. Define product functions associated with customers’ needs, and analyze their performance criteria

3. Prioritize the functions according to the end customer’s real needs

4. Breakdown the product’s costs over all the functions

5. Assess the product’s performance level for each performance criteria

6. Define macro scenarios of interest (core product and optional functions)

6. Define macro scenarios of interest (core product and optional functions)

Once these 6 steps are properly executed, you can start building value optimization solutions. Two axes can and should be used for that purpose.

Axe 1: Creativity session, involving both your internal teams and external suppliers.

Cross-functional sessions serve as an enabling platform for fostering innovation, disruption, and are instrumental in identifying practical and viable solutions.

Axe 2: Thorough and comprehensive benchmark.

This involves a detailed examination of industry standards, market trends, and the functionalities offered by competitors. By doing so, you ensure that your product functions are not only in line with the latest advancements but also positioned competitively within the market landscape.

Case study: Deploying Design-to-Value in the Defense sector

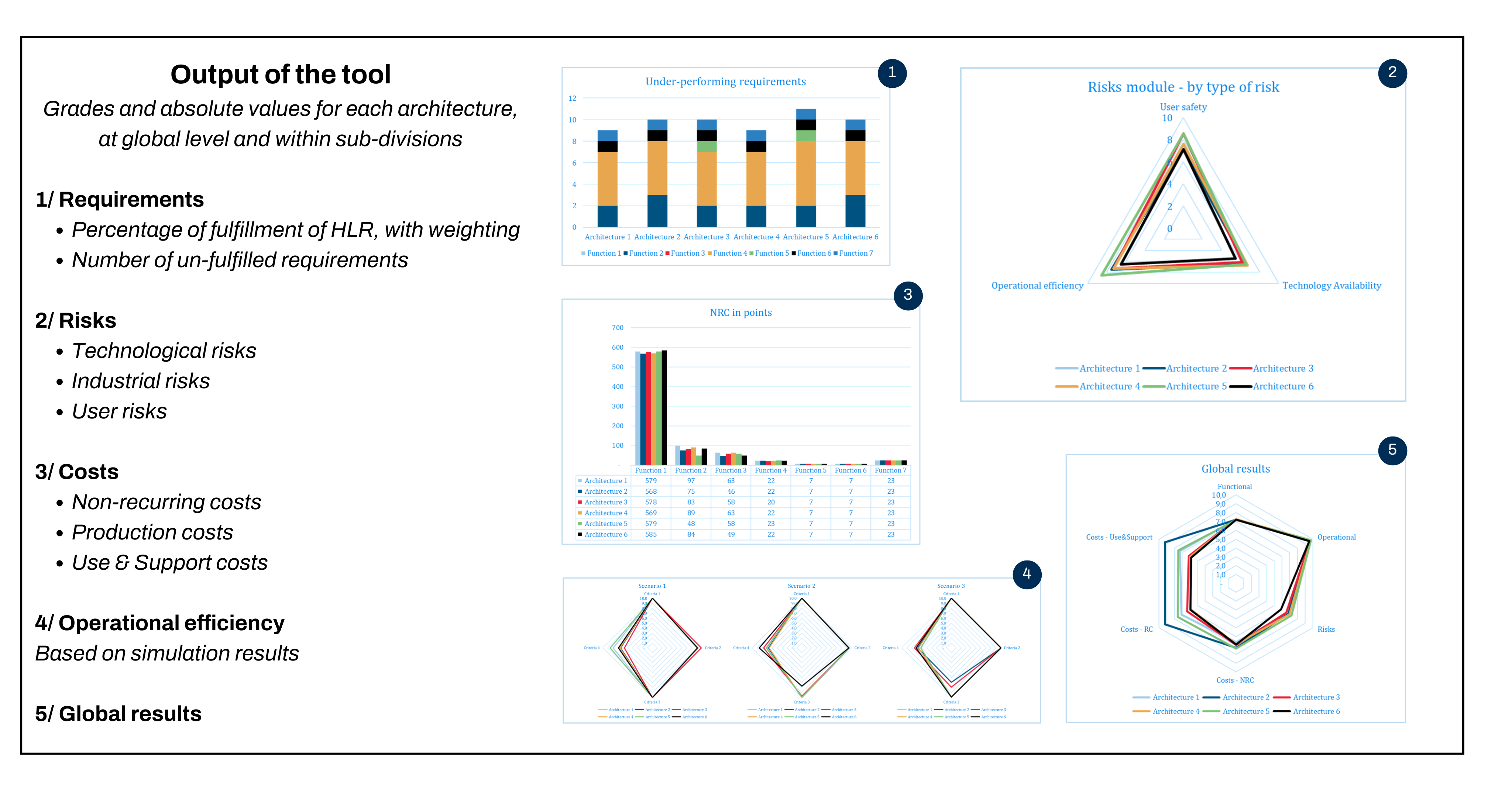

Project’s objective: Define and deploy a shared Value Analysis Method between 2 government agencies and 3 prime companies in the early development stage of a major multinational defense system

Methods leveraged:

- Customer needs formalization and product’s functions identification through HLR “High Level Requirements”

- Functions prioritization through several options: simple function rating, simple cross-sorting, multiple cross-sorting

- Functional cost breakdown through dedicated workshops led using the cost breakdown matrix method

- Product’s performance level assessment & product’s value rating through dedicated methods: simple grading or exchange rates (or monetary exchange rates)

Project’s result: Interactive & flexible tool allowing:

- Quick comparison of technological & architectural choices between concepts

- Direct assessment of client’s specifications impacts on the value of each concept (focus on costs, risks, operational efficiency), to help driving key value choices at early development stage

- Flexible self-generated tool allowing incremental refinement of assessment method with the progressive input data maturity evolution

Key success factors to implement Design-To-Value method in Manufacturing.

- Creativity sessions must activate cross-functional teams to ensure innovation and disruption in particular by the sharing of irritants.

- A structured feedback loop must be established to facilitate continuous learning and adaptation, forming the basis for a culture of continual improvement.

- It is imperative to use appropriate tools for structuring value analysis, ensuring a thorough and exhaustive examination of product value.

Recognition and incorporation of customer/user-perceived value is mandatory at every stage of the product life cycle, from the product design to the dismantling, through operations, customer delivery and MRO.

Authors : Jean-Charles Dickeli, Ilyès Methia, Nicolas Barat